Possess Sea Industrial Co., Ltd. - Materials Division

Professional Neoprene Fabric Manufacturer, Supplier and Exporter in China

Professional Neoprene Fabric Manufacturer, Supplier and Exporter in China

Contact: Ms.Maggie, Mobile / WhatsApp: +86 138 168 15888, E-mail: maggie@neoprene.asia

SBR & SCR Neoprene Sponge, Styrene Butadiene Rubber Sponge - Manufacturer

"SBR Neoprene" scientific name "Styrene Butadiene Rubber", is an elastomeric synthetic rubber produced by styrene and butadiene polymerization based on petroleum. It was invented by Walter Bock of IG Farben AG in the 1930s. The initial design It is used to replace natural rubber to make tires.

In the 1950s and 1960s, companies in the United States and Japan began to use chloroprene rubber to make wetsuits. Later, South Korea, Taiwan, and China also joined the ranks. The chloroprene rubber used to make wetsuits is in the form of closed-cell foam (honeycomb structure), which can be processed to the required thickness and placed between other fabric sheets (such as polyester, nylon, spandex, etc.).

Based on cost considerations, at the end of the 20th century, styrene butadiene rubber began to be used to make wetsuits, also in the form of closed-cell foam (honeycomb structure), commonly referred to as SBR in the industry, and used to replace chloroprene rubber in some applications. The cost of styrene butadiene rubber sponge is significantly lower than that of chloroprene rubber sponge, but its performance is also far behind that of chloroprene rubber sponge. Later, in order to achieve a balance between cost and performance, a mixture of styrene butadiene rubber and chloroprene rubber was developed, which is usually called SCR in the industry.

Normative Interpretation: "Neoprene" = "CR" ≠ "SCR" ≠ "SBR"

"Neoprene" just refers to the "CR" (Chloroprene Rubber), but now the industry "Neoprene" include "CR" (Chloroprene Rubber), "SCR" (Chloroprene & Styrene Butadiene Rubber), "SBR" (Styrene Butadiene Rubber).

Styrene Butadiene Rubber Sponge (SBR)

Explain: "SBR Neoprene Sponge" is a synthetic rubber produced by polymerization of styrene and butadiene. This is a low grade neoprene sponge.

Features: "SBR Neoprene Sponge" has excellent cushioning and warmth retention, but has poor compression resistance and is cheap.

Color: Black, Cream, Aqua, White.

Chloroprene & Styrene Butadiene Rubber Sponge (SCR)

Explain: "SCR Neoprene Sponge" is a mixture of CR (Chloroprene Rubber) and SBR (Styrene Butadiene Rubber) and is widely used in the production of various related products. This is a medium grade neoprene sponge.

Features: "SCR Neoprene Sponge" combines the properties of both CR and SBR.

Color: Black, Cream.

Neoprene Sponge Color:

| Neoprene Type | CR | SCR | SBR |

| Sponge Color | Black, Cream | Black, Cream | Black, Cream, Aqua, White |

Neoprene sponge color is black, cream, aqua and white. Usually we use black, but if light color fabric is laminated, the use of cream, aqua or white neoprene sponge is better, this collocation can better reflect the color and bright of the light color fabric. If use the black neoprene sponge will light color fabric dark and distorted. But the cost of cream, aqua or white neoprene sponge is higher than the black neoprene sponge.

Neoprene Sponge Size & Thickness:

| Size (inch) | 51″x83″ | 56″x83″ | 60″x83″ |

| 51″x130″ | 56″x130″ | 60″x130″ | |

| 51″x170″ | 56″x170″ | 60″x170″ | |

| 51″x260″ | 56″x260″ | 60″x260″ | |

| Thickness | 10mm - 44mm | ||

Neoprene sponge is produced by foaming mold. The size of the mold defines the size of the neoprene sponge.

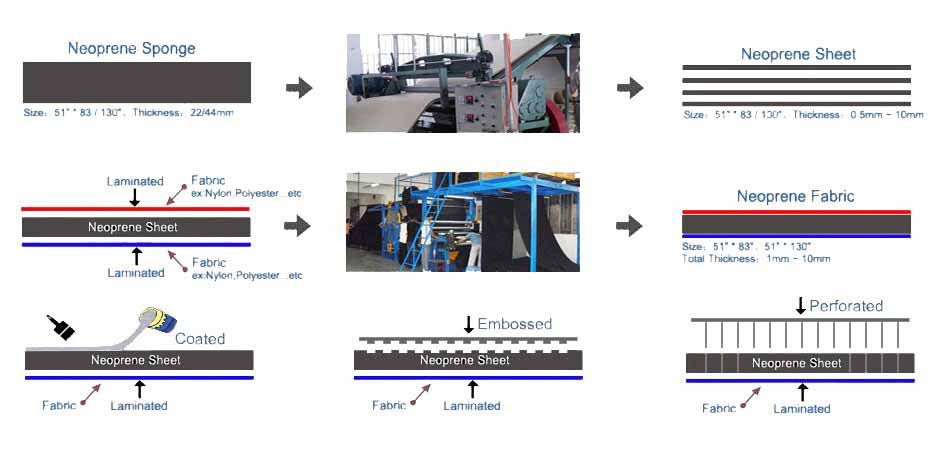

Neoprene Fabric Production Processing:

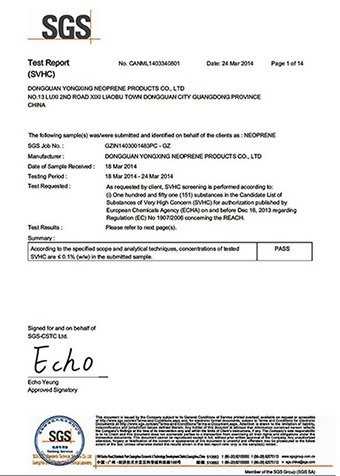

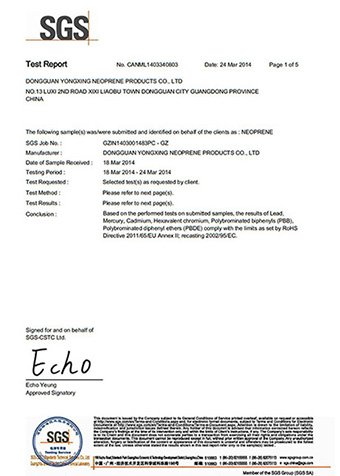

SGS Test Report (ECO-Neoprene Fabric):

SGS REACH Test

SGS RoHS Test

SGS Toxic Elements Test

SGS Toxic Elements Test

Description of SGS Test Products:

ECO-Neoprene Sponge Laminated ECO-Fabric made of Nylon, Polyester, Lycra, Dyed and Finished.

Limestone Based Eco-Friendly Rubber Sponge Can Fulfill The Below International Standards:

| Oeko-Tex Standard 100 |

Class II |

| REACH | 151 substances in the Candidate List of Substances of Very High Concern (SVHC) for Regulation (EC) No 1907/2006 concerning the REACH |

| RoHS | Restriction of Hazardous Substances - RoHS 2.0 Directive 2011/65/EU Annex II; Recasting 2002/95/EC |

| CPSIA | USA Public Law 110-314 (Consumer Product Safety Improvement Act of 2008, CPSIA) - 1) Lead in accessible substrate materials 2) Phthalates |

| PAHs | Comply with (Category 2) of ZEK 01.4-08 of German ZLS and its amendments |

| Toxic Elements | Migration of Certain Elements - EN 71-3:1994+A1:2000+AC:2002 |