Possess Sea Industrial Co., Ltd. - Materials Division

Professional Neoprene Fabric Manufacturer, Supplier and Exporter in China

Professional Neoprene Fabric Manufacturer, Supplier and Exporter in China

Contact: Ms.Maggie, Mobile / WhatsApp: +86 138 168 15888, E-mail: maggie@neoprene.asia

SBR, SCR, CR, Neoprene Rubber Sponge - Manufacturer

The neoprene sponge material we use is a closed-end foamed elastomer (honeycomb structure) with extremely low density (light weight), high flexibility and excellent thermal insulation properties. At present, we can provide various types of products such as chloroprene rubber and styrene butadiene rubber sponge made from petroleum extracts, eco-friendly neoprene sponge made from limestone, and bio-based rubber sponge made from renewable raw materials.

Normative Interpretation: "Neoprene" = "CR" ≠ "SCR" ≠ "SBR"

Note: "Neoprene" just refers to the "CR" (Chloroprene Rubber), but now the industry "Neoprene" include "CR" (Chloroprene Rubber), "SCR" (Chloroprene & Styrene Butadiene Rubber), "SBR" (Styrene Butadiene Rubber).

CR Neoprene Sponge (Chloroprene Rubber)

"CR Neoprene Sponge" is a synthetic rubber produced by polymerization of chloroprene. It has good chemical stability and maintains flexibility over a wide temperature range. This is a high grade neoprene sponge.

Features: "CR Neoprene Sponge" has excellent elasticity, strength, pressure resistance and warmth retention, seawater resistance, chemical resistance and flame retardancy.

Applications: Wetsuit, surf suit, triathlon wetsuit, spearfishing wetsuit, drysuit, swimsuit, immersion suit, sports protective gear, medical protective gear and horse protective gear etc.

SCR Neoprene Sponge (Chloroprene & Styrene Butadiene Rubber)

"SCR Neoprene Sponge" is a mixture of CR (Chloroprene Rubber) and SBR (Styrene Butadiene Rubber) and is widely used in the production of various related products. This is a medium grade neoprene sponge.

Features: "SCR Neoprene Sponge" combines the properties of both CR and SBR.

Applications: Wetsuit, surf suit, swimsuit, PFD, sports protective gear, medical protective gear, horse protective gear, gloves, shoes and bag etc.

SBR Neoprene Sponge (Styrene Butadiene Rubber)

"SBR Neoprene Sponge" is a synthetic rubber produced by polymerization of styrene and butadiene. This is a low grade neoprene sponge.

Features: "SBR Neoprene Sponge" has excellent cushioning and warmth retention, but has poor compression resistance and is cheap.

Applications: Wetsuit, surf suit, swimsuit, PFD, waders, sports protective gear, medical protective gear, gloves, Shoes, bag, case, sleeve, cover, cooler and pad etc.

Eco-Friendly Neoprene Sponge (Limestone-Based)

"Eco-Friendly Neoprene Sponge" is a synthetic rubber produced by polymerization of acetylene gas produced by burning limestone, which can reduce the consumption and dependence on petroleum. This is a green and environmentally friendly low-toxic rubber sponge foam.

Features: "Eco-Friendly Neoprene Sponge" has uniform microcells cells that can withstand stretching and bending for a longer period of time.

Applications: Eco-Friendly products.

Recycled Rubber Sponge (Recycled Production Waste)

"Recycled Rubber Sponge" uses waste produced in production as raw material, and re-polymerizes it by blending with virgin material to obtain a usable product.

Features: "Recycled Rubber Sponge" promotes the recycling of production waste.

Applications: Wetsuits, shoes and bag.

Biomass Based Rubber Sponge (Polyisoprene Rubber)

"Biomass-based rubber sponge" by screening the main raw materials of polyisoprene rubber and fatty acid ester, adding non-metallic minerals, chitin and biomass based carbon etc, it is transformed into biomass based polymer sponge.

Features: "Biomass-based rubber sponge" used to replace petroleum-based or mineral-based rubber sponges, minimize the use of petrochemical raw materials and the extraction of minerals, and minimize the impact on the environment.

Applications: Shoes and bag.

Neoprene Sponge Color:

| Neoprene Type | CR | SCR | SBR |

| Sponge Color | Black, Cream | Black, Cream | Black, Cream, Aqua, White |

Neoprene sponge color is black, cream, aqua and white. Usually we use black, but if light color fabric is laminated, the use of cream, aqua or white neoprene sponge is better, this collocation can better reflect the color and bright of the light color fabric. If use the black neoprene sponge will light color fabric dark and distorted. But the cost of cream, aqua or white neoprene sponge is higher than the black neoprene sponge.

Neoprene Sponge Size & Thickness:

| Size (inch) | 51″x83″ | 56″x83″ | 60″x83″ |

| 51″x130″ | 56″x130″ | 60″x130″ | |

| 51″x170″ | 56″x170″ | 60″x170″ | |

| 51″x260″ | 56″x260″ | 60″x260″ | |

| Thickness | 10mm - 44mm | ||

Neoprene sponge is produced by foaming mold. The size of the mold defines the size of the neoprene sponge.

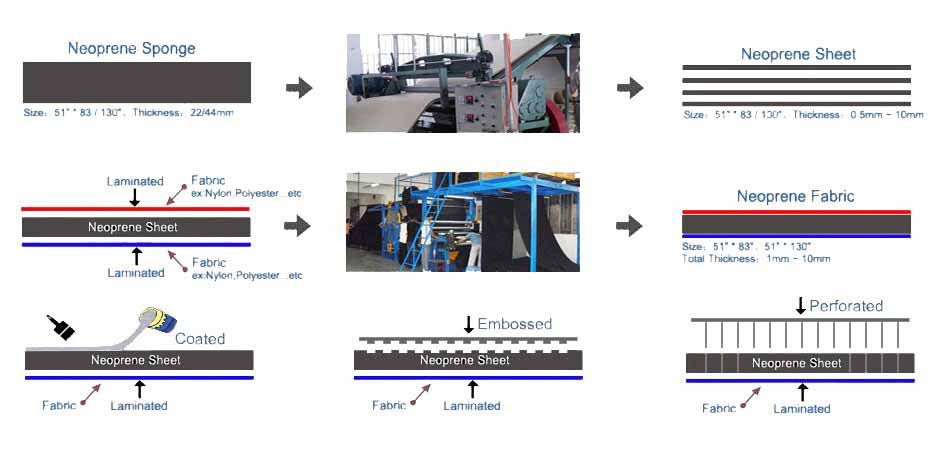

Neoprene Fabric Production Processing:

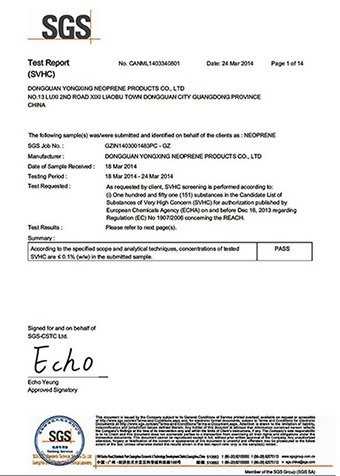

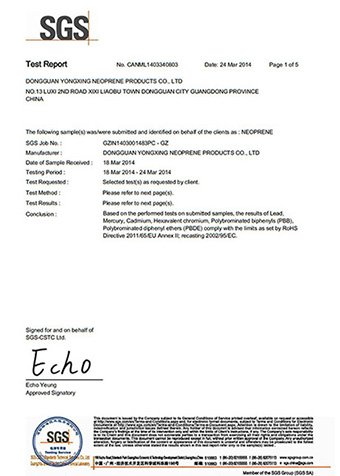

SGS Test Report (ECO-Neoprene Fabric):

SGS REACH Test

SGS RoHS Test

SGS Toxic Elements Test

SGS Toxic Elements Test

Description of SGS Test Products:

ECO-Neoprene Sponge Laminated ECO-Fabric made of Nylon, Polyester, Lycra, Dyed and Finished.

Limestone Based Eco-Friendly Rubber Sponge Can Fulfill The Below International Standards:

| Oeko-Tex Standard 100 |

Class II |

| REACH | 151 substances in the Candidate List of Substances of Very High Concern (SVHC) for Regulation (EC) No 1907/2006 concerning the REACH |

| RoHS | Restriction of Hazardous Substances - RoHS 2.0 Directive 2011/65/EU Annex II; Recasting 2002/95/EC |

| CPSIA | USA Public Law 110-314 (Consumer Product Safety Improvement Act of 2008, CPSIA) - 1) Lead in accessible substrate materials 2) Phthalates |

| PAHs | Comply with (Category 2) of ZEK 01.4-08 of German ZLS and its amendments |

| Toxic Elements | Migration of Certain Elements - EN 71-3:1994+A1:2000+AC:2002 |