Possess Sea Industrial Co., Ltd. - Materials Division

Professional Neoprene Fabric Manufacturer, Supplier and Exporter in China

Professional Neoprene Fabric Manufacturer, Supplier and Exporter in China

Contact: Ms.Maggie, Mobile / WhatsApp: +86 138 168 15888, E-mail: maggie@neoprene.asia

Eco-Friendly Neoprene Sponge, Limestone Based Rubber Sponge - Manufacturer

"Eco-Friendly Neoprene Sponge" is not produced by petroleum extraction products, but is a synthetic rubber produced by polymerization of acetylene gas produced by burning limestone. It has uniform microporous cells and can withstand stretching and bending for a longer period of time. Can reduce the consumption and dependence on oil.

The presence of hazardous substances such as polycyclic aromatic hydrocarbon compounds (PAHs) in synthetic rubber produced from petroleum refined products is inevitable. Synthetic rubber produced based on burning limestone has relatively low content of related harmful substances and the production process is more environmentally friendly. This is why it is also called eco-friendly neoprene sponge.

Currently, we can provide limestone neoprene sponges from Japan and Taiwan. The products comply with many international green directives and standards such as PAHs, REACH / SVHC, RoHS, CPSIA etc, and have passed Oeko-Tex® Standard 100 Class II certification, and can provide CR, SCR, SBR multiple models of products.

ECO-CR01 Limestone Based Eco-Friendly Neoprene Sponge

Elongation Rate: 650% ↑。

Hardness: 2 ↓ (Type C).

Composition: 100% CR.

Applications: Wetsuit and spearfishing wetsuit etc.

ECO-CR02 Limestone Based Eco-Friendly Neoprene Sponge

Elongation Rate: 420% ↑。

Hardness: 2 - 4 (Type C).

Composition: 100% CR.

Applications: Wetsuit, surf suit, sports protective gear, medical protective gear, bag and gloves etc.

ECO-CR03 Limestone Based Eco-Friendly Neoprene Sponge

Elongation Rate: 440% ↑。

Hardness: 4 - 6 (Type C).

Composition: 100% CR.

Applications: Wetsuit, surf suit, sports protective gear, medical protective gear, bag and gloves etc.

ECO-CR04 Limestone Based Eco-Friendly Neoprene Sponge

Elongation Rate: 200% ↑。

Hardness: 21 ± 5 (Type C).

Composition: 100% CR.

Applications: Insole and protection pad etc.

ECO-SCR05 Limestone Based Eco-Friendly Neoprene Sponge

Elongation Rate: 300% ↑。

Hardness: 4 - 6 (Type C).

Composition: SCR (30% CR + 70% SBR).

Applications: Sports protective gear, medical protective gear, horse protective gear, bag, gloves and shoes etc.

ECO-SBR06 Limestone Based Eco-Friendly Neoprene Sponge

Elongation Rate: 250% ↑。

Hardness: 7 - 9 (Type C).

Composition: 100% SBR.

Applications: Sports protective gear, medical protective gear, horse protective gear, bag, gloves and shoes etc.

Limestone Based Eco-Friendly Neoprene Sponge:

| Type | Composition | Color | Elongation Rate | Hardness (Type C) |

200% Modulus (kg/cm2) |

Size |

| ECO-CR01 | 100% CR | Black | 650% ↑ | 2 ↓ | 0.5 - 1.5 | 51" x 83" 51" x 130" |

| ECO-CR02 | 100% CR | Black | 420% ↑ | 2 - 4 | 1 - 3 | 51" x 83" 51" x 130" |

| ECO-CR03 | 100% CR | Black | 440% ↑ | 4 - 6 | 1.3 - 3.3 | 51" x 83" 51" x 130" |

| ECO-CR04 | 100% CR | Black | 200% ↑ | 21 ± 5 | / | 47" x 75" |

| ECO-SCR05 | SCR 30% CR + 70% SBR |

Black | 300% ↑ | 4 - 6 | 2 - 4 | 51" x 83" 51" x 130" |

| ECO-SBR06 | 100% SBR | Black | 250% ↑ | 7 - 9 | 2.5 - 4.5 | 51" x 83" 51" x 130" |

Limestone Based Eco-Friendly Rubber Sponge Can Fulfill The Below International Standards:

| Oeko-Tex Standard 100 |

Class II |

| REACH | 151 substances in the Candidate List of Substances of Very High Concern (SVHC) for Regulation (EC) No 1907/2006 concerning the REACH |

| RoHS | Restriction of Hazardous Substances - RoHS 2.0 Directive 2011/65/EU Annex II; Recasting 2002/95/EC |

| CPSIA | USA Public Law 110-314 (Consumer Product Safety Improvement Act of 2008, CPSIA) - 1) Lead in accessible substrate materials 2) Phthalates |

| PAHs | Comply with (Category 2) of ZEK 01.4-08 of German ZLS and its amendments |

| Toxic Elements | Migration of Certain Elements - EN 71-3:1994+A1:2000+AC:2002 |

Oeko-Tex® Standard 100 Test Standard (Executed from April 1, 2018):

| Product Class | Class I | Class II | Class III | Class IV |

| Baby | In Direct Contact With Skin | With No Direct Contact With Skin | Decoration Material | |

| pH value | ||||

| 4.0 - 7.5 | 4.0 - 7.5 | 4.0 - 9.0 | 4.0 - 9.0 | |

| Formaldehyde, free and partially releasable [mg/kg] | ||||

| Law 112 / 112 法 | n.d. | < 75 | < 150 | < 300 |

| Extractable (heavy) metals [mg/kg] | ||||

| Sb (Antimony) | < 30.0 | < 30.0 | < 30.0 | |

| As (Arsenic) | < 0.2 | < 1.0 | < 1.0 | < 1.0 |

| Pb (Lead) | < 0.2 | < 1.0 | < 1.0 | < 1.0 |

| Cd (Cadmium) | < 0.1 | < 0.1 | < 0.1 | < 0.1 |

| Cr (Chromium) | < 1.0 | < 2.0 | < 2.0 | < 2.0 |

| Cr (VI)铬 | < 0.5 | < 0.5 | < 0.5 | < 0.5 |

| Co (Cobalt) | < 1.0 | < 4.0 | < 4.0 | < 4.0 |

| Cu (Copper) | < 25.0 | < 50.0 | < 50.0 | < 50.0 |

| Ni (Nickel) | < 1.0 | < 4.0 | < 4.0 | < 4.0 |

| Hg (Mercury) | < 0.02 | < 0.02 | < 0.02 | < 0.02 |

| Ba (Barium) | < 1000 | < 1000 | < 1000 | < 1000 |

| Se (Selenium) | < 100 | < 100 | < 100 | < 100 |

| Polycyclic aromatic hydrocarbons (PAHs) [mg/kg] | ||||

| Benzo[a]pyrene | < 0.5 | < 1.0 | < 1.0 | < 1.0 |

| Benzo[e]pyrene | < 0.5 | < 1.0 | < 1.0 | < 1.0 |

| Benzo[a]anthracene | < 0.5 | < 1.0 | < 1.0 | < 1.0 |

| Chrysene | < 0.5 | < 1.0 | < 1.0 | < 1.0 |

| Benzo[b]fluoranthene | < 0.5 | < 1.0 | < 1.0 | < 1.0 |

| Benzo[j]fluoranthene | < 0.5 | < 1.0 | < 1.0 | < 1.0 |

| Benzo[k]fluoranthene | < 0.5 | < 1.0 | < 1.0 | < 1.0 |

| Dibenzo[a,h]anthracene | < 0.5 | < 1.0 | < 1.0 | < 1.0 |

| Sum 24 PAHs | < 5.0 | < 10.0 | < 10.0 | < 10.0 |

Note: "Limestone Based Eco-Friendly Rubber Sponge" has passed Oeko-Tex® Standard 100 Class II certification.

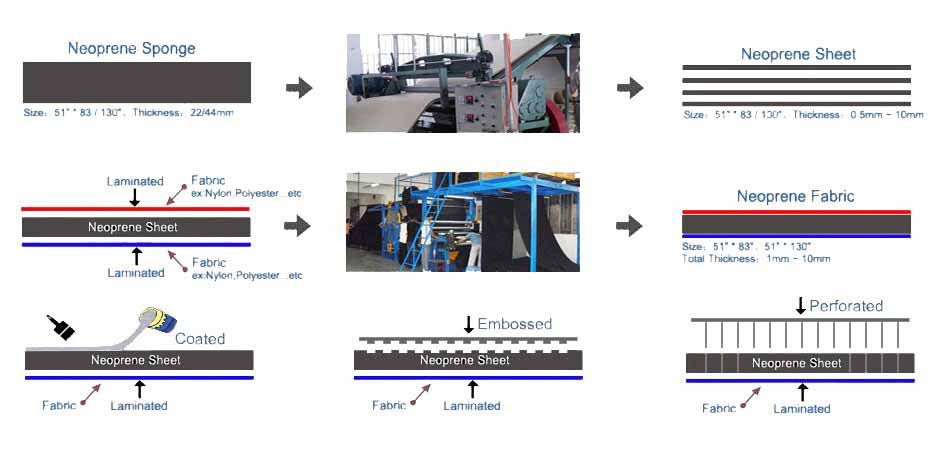

Neoprene Fabric Production Processing: