Possess Sea Industrial Co., Ltd. - Materials Division

Professional Neoprene Fabric Manufacturer, Supplier and Exporter in China

Professional Neoprene Fabric Manufacturer, Supplier and Exporter in China

Contact: Ms.Maggie, Mobile / WhatsApp: +86 138 168 15888, E-mail: maggie@neoprene.asia

Neoprene Fabric, Wetsuit Fabric - Manufacturer

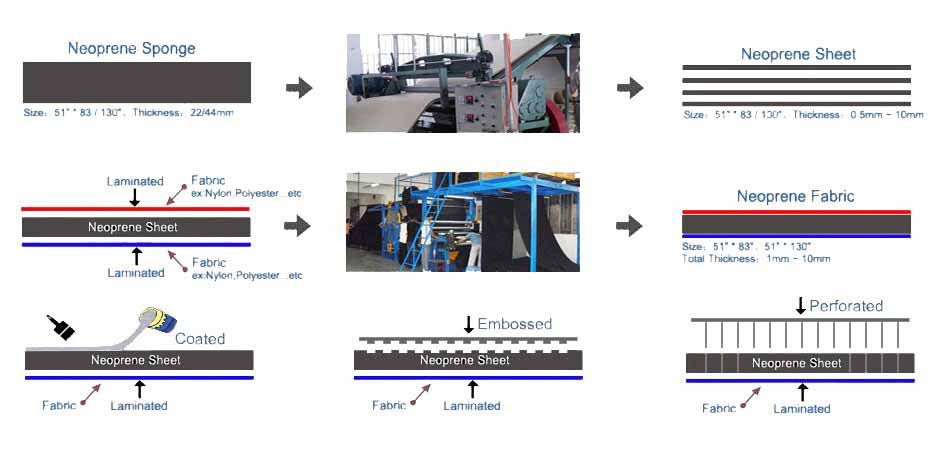

"Neoprene Fabric" is made of "Neoprene Sponge" (foamed elastomer in closed cell form). The "Neoprene Sponge" is the middle layer, and the surface is usually "Laminated" the fabric, or "Smooth Skin" or "Coated". Some products also use the "Embossed" and "Perforated" processes. The main features are waterproof, warm, and have excellent cushioning protection. And also be breathable processing for customer needs. "Neoprene Fabric" was originally used mainly for wetsuits, so it is also called "Wetsuit Fabric", and now we also use it extensively to make other products.

We are a professional neoprene factory, using different kinds of neoprene sponges and fabrics from different countries or regions, according to the needs of customers, we can combine them into different grades and types of "Neoprene Fabric". We can provide a combination of high grade materials such as CR sponge + super stretch fabric, and also provide a combination of low grade materials such as SBR sponge + polyester fabric, all depending on the positioning and budget of the customer's products. The price difference between different types of neoprene sponges and fabrics is very large (the price ratio of CR, SCR and SBR sponges is about 4 : 2 : 1), and we promise to provide a veritable product.

The width of the "Neoprene Wetsuit Fabric" is 51 inch / 1.3 meter / 1.41 yard, the volume is large, and the cargo value is not high. For international customers, we use express to send A4 size samples, large orders use sea. send products of full-size by express or air is very expensive, so DIY or small orders are not appropriate. It is suggested to seek local distributors to purchase the products, or to order end products directly from our product department.

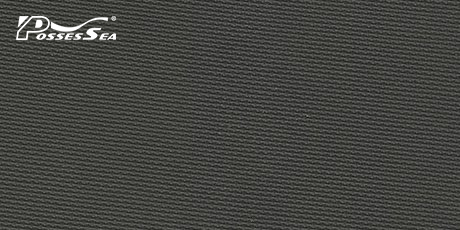

Laminated Neoprene Fabric

Explain: "Laminated" means using glue to stick the fabric to the "Neoprene Sponge" surface to increase the surface strength (tear and abrasion resistance) of the neoprene sponge, and make the neoprene sponge have the characteristics of the fabric. This is the most common processing technique.

Applications: "Laminated Neoprene Fabric" is widely used in the production of various related products, commonly used fabric types are polyester, nylon and lycra etc.

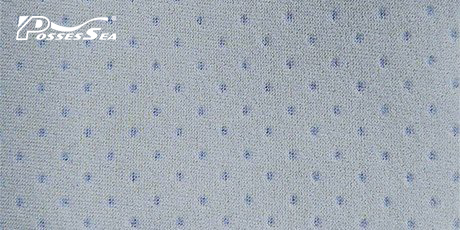

Coated Neoprene Fabric

Explain: "Coated" refers to the use of polyurethane polymer materials to coat he surface of "Neoprene Sponge" to increase the surface strength and smoothness of the neoprene sponge, to prevent moisture accumulation and reduce frictional resistance in water, and to impart neoprene sponges are more colors. You can choose to add extra titanium to the "Coated" to improve warmth performance.

Applications: "Coated Neoprene Fabric" is commonly used to make high grade products such as triathlon wetsuit and spearfishing wetsuit etc.

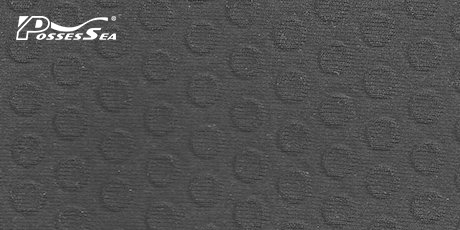

Embossed Neoprene Fabric

Explain: "Embossed" refers to the use of different patterns of the mold to embossed the surface of "Neoprene Sponge", so that the surface presents a different pattern to increase the surface strength of the neoprene sponge, to achieve beauty, anti-slip and reduce friction in the water resistance and other functions.

Applications: "Embossed Neoprene Fabric" is commonly used to make products that require increased surface strength or anti-slip effects.

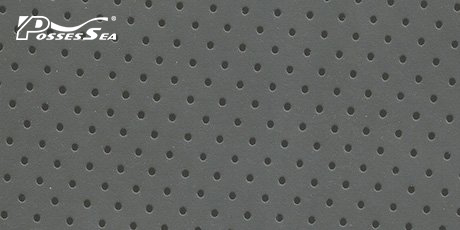

Perforated Neoprene Fabric

Explain: "Perforated" refers to the use of different shapes of molds to perforated the "Neoprene Sponge" to create holes of various shapes and sizes to increased breathability, reduce weight and enhance design. There are two types: "Visible Perforated" is to laminated the neoprene sponge with the fabric and then perforated, the holes is visible. "Inside Perforated" is to first perforated the neoprene sponge and then laminated the fabric, the holes are not visible.

Applications: "Perforated Neoprene Fabric" is commonly used to make products that require increased breathability or appearance.

Neoprene Material Explain:

Normative Interpretation: "Neoprene" = "CR" ≠ "SCR" ≠ "SBR"

"Neoprene" just refers to the "CR" (Chloroprene Rubber), but now the industry "Neoprene" include "CR" (Chloroprene Rubber), "SCR" (Chloroprene & Styrene Butadiene Rubber), "SBR" (Styrene Butadiene Rubber).

Neoprene Sponge Color:

| Neoprene Type | CR | SCR | SBR |

| Sponge Color | Black, Cream | Black, Cream | Black, Cream, Aqua, White |

Neoprene sponge color is black, cream, aqua and white. Usually we use black, but if light color fabric is laminated, the use of cream, aqua or white neoprene sponge is better, this collocation can better reflect the color and bright of the light color fabric. If use the black neoprene sponge will light color fabric dark and distorted. But the cost of cream, aqua or white neoprene sponge is higher than the black neoprene sponge.

Neoprene Fabric Size & Thickness:

| Size (inch) | 51″x83″ | 56″x83″ | 60″x83″ |

| 51″x130″ | 56″x130″ | 60″x130″ | |

| 51″x170″ | 56″x170″ | 60″x170″ | |

| 51″x260″ | 56″x260″ | 60″x260″ | |

| Thickness | 1mm - 10mm | ||

Neoprene sponge is produced by foaming mold. The size of the mold defines the size of the neoprene sponge so the size of the neoprene sponge defines the size of the neoprene fabric.

Neoprene Fabric Quotation Explain:

Usually use "Sheet" or "Piece" as the unit of quotation, in which the cost of neoprene sponge is calculated by thickness, and the cost of fabric and processing is calculated by surface: "Neoprene Sponge Cost" (Thickness, Size and Type) + "Fabric Cost" (Size and Type) + "Processing Cost" (Laminated / Coated / Embossed / Perforated).

We do not recommend the use of "Meter" or "Yard" as the unit of quotation, because the actual length of the neoprene sponge block will be longer than the standard size. Using "Meter" or "Yard" as the unit of quotation is beneficial to the factory and unfair to the customer.

Many customers feel that using "Meter" or "Yard" as the quotation unit will get continuous products, and using "Sheet" or "Piece" as the quotation unit will get single piece product, that it is incorrect. The product is continuous or single piece, and has nothing to do with the unit of quotation, only related to the packaging method, "Carton Package" and "Roll Package" are continuous products, and "Crate Package" is a single piece product.

Continuous Product Explain: We use glue to connect the neoprene sponge and then laminated the fabric so that the neoprene fabric looks continuous. But because the neoprene sponge in the middle layer has a connected by glue, can not use continuously, can only use sheet-by-sheet.

Example: SBR Neoprene Double Laminated Standard Polyester Fabric

| Item | Unit Price | Total Thickness 2.0mm Price | Total Thickness 3.0mm Price |

| Size | 51″ x 130″ / 1.3M x 3.3M / 1.41Y x 3.58Y | ||

| SBR Neoprene | USD $1.912 / mm | USD $3.059 / 1.6mm | USD $4.971 / 2.6mm |

| Polyester Fabric | USD $2.059 / Side | USD $4.118 / Double Side | USD $4.118 / Double Side |

| Laminated | USD $0.885 / Side | USD $1.77 / Double Side | USD $1.77 / Double Side |

| Total | / | USD $8.947 / Sheet or USD $2.711 / Meter or USD $2.494 / Yard |

USD $10.859 / Sheet or USD $3.291 / Meter or USD $3.027 / Yard |

Explain: Total Thickness 2.0mm = Neoprene Sponge Thickness 1.6mm + Double Side Standard Polyester Fabric Thickness 0.4mm

Total Thickness 3.0mm = Neoprene Sponge Thickness 2.6mm + Double Side Standard Polyester Fabric Thickness 0.4mm

Example: SBR Neoprene Double Laminated Standard Nylon Fabric

| Item | Unit Price | Total Thickness 2.0mm Price | Total Thickness 3.0mm Price |

| Size | 51″ x 130″ / 1.3M x 3.3M / 1.41Y x 3.58Y | ||

| SBR Neoprene | USD $1.912 / mm | USD $2.868 / 1.5mm | USD $4.78 / 2.5mm |

| Nylon Fabric | USD $4.191 / Side | USD $8.382 / Double Side | USD $8.382 / Double Side |

| Laminated | USD $0.885 / Side | USD $1.77 / Double Side | USD $1.77 / Double Side |

| Total | / | USD $13.02 / Sheet or USD $3.945 / Meter or USD $3.63 / Yard |

USD $14.932 / Sheet or USD $4.525 / Meter or USD $4.163 / Yard |

Explain: Total Thickness 2.0mm = Neoprene Sponge Thickness 1.5mm + Double Side Standard Nylon Fabric Thickness 0.5mm

Total Thickness 3.0mm = Neoprene Sponge Thickness 2.5mm + Double Side Standard Nylon Fabric Thickness 0.5mm

Note: The above price is for reference only. The final price will fluctuate slightly due to the change of raw material price, exchange rate fluctuation and order quantity.

Neoprene Fabric Production Processing:

Neoprene Fabric Packaging Method:

Neoprene Fabric - Roll Package

Explain: Wrap the continuously spliced "Neoprene Fabric" is wrapped on the paper core. The number of spliced pieces depends on the thickness of the neoprene fabric, usually between 2 - 20 sheets. Finally, use polypropylene woven fabric or polyethylene polyethylene film to wrap.

Advantages & Disadvantages: The cost of this type of packaging is low, but neoprene fabric is susceptible to uneven extrusion and is not suitable for customers with high requirements.

Neoprene Fabric - Carton Package

Explain: Similar to the roll package, the continuously spliced "Neoprene Fabric" is wrapped on the paper core and finally placed in the carton.

Advantages & Disadvantages: Relative protection is better than roll package, and the corresponding packaging cost is higher than roll package.

Neoprene Fabric - Crate Package

Explain: There are 2 forms, crate or tray + large overall carton. The "Neoprene Fabric" is stacked in a crate or a large carton.

Advantages & Disadvantages: Usually only used for 51" x 83" specific size neoprene fabric, other sizes will be a waste of container space, the neoprene fabric is squeezed evenly and has good protection.

Neoprene Fabric Packaging List:

| Packing Method | Crate Package | Carton Package | Roll Package |

| Thickness / Size | 51″x83″ | 51″x130″ | 51″x130″ |

| 1.0mm | 800 | 30 | 20 |

| 1.5mm | 530 | 20 | 13 |

| 2.0mm | 400 | 15 | 10 |

| 2.5mm | 320 | 12 | 8 |

| 3.0mm | 270 | 10 | 6 |

| 3.5mm | 230 | 8 | 5 |

| 4.0mm | 200 | 7 | 5 |

| 4.5mm | 180 | 6 | 4 |

| 5.0mm | 160 | 6 | 4 |

| 5.5mm | 145 | 5 | 3 |

| 6.0mm | 130 | 5 | 3 |

| 6.5mm | 120 | 4 | 3 |

| 7.0mm | 115 | 4 | 2 |

| 7.5mm | 105 | 4 | 2 |

| 8.0mm | 100 | 3 | 2 |

| 8.5mm | 95 | 3 | 2 |

| 9.0mm | 90 | 3 | 2 |

| 9.5mm | 85 | 3 | 2 |

| 10.0mm | 80 | 3 | 2 |

| Volume of 20 'Container | 8 Crates | 144 Cartons | 240 Rolls |

Limestone Based Eco-Friendly Rubber Sponge Can Fulfill The Below International Standards:

| Oeko-Tex Standard 100 |

Class II |

| REACH | 151 substances in the Candidate List of Substances of Very High Concern (SVHC) for Regulation (EC) No 1907/2006 concerning the REACH |

| RoHS | Restriction of Hazardous Substances - RoHS 2.0 Directive 2011/65/EU Annex II; Recasting 2002/95/EC |

| CPSIA | USA Public Law 110-314 (Consumer Product Safety Improvement Act of 2008, CPSIA) - 1) Lead in accessible substrate materials 2) Phthalates |

| PAHs | Comply with (Category 2) of ZEK 01.4-08 of German ZLS and its amendments |

| Toxic Elements | Migration of Certain Elements - EN 71-3:1994+A1:2000+AC:2002 |