Possess Sea Industrial Co., Ltd. - Materials Division

Professional Neoprene Fabric Manufacturer, Supplier and Exporter in China

Professional Neoprene Fabric Manufacturer, Supplier and Exporter in China

Contact: Ms.Maggie, Mobile / WhatsApp: +86 138 168 15888, E-mail: maggie@neoprene.asia

Embossed Neoprene Sheet, Textured Neoprene Fabric - Manufacturer

"Embossed" refers to embossed the surface of the "Neoprene Sponge" with a different pattern of mold, so that the surface presents a different pattern to increase the surface strength of the neoprene sponge, to achieve beauty, anti-slip and reduce friction in the water resistance and other functions. "Embossed Neoprene" is commonly used to make products that require increased surface strength or anti-slip effects.

There are three types: "Embossed Skin", "Embossed Cell" and "Embossed Fabric". The "Embossed Skin" and "Embossed Cell" are usually embossed on one side and laminated fabric on the other side. The "Embossed Fabric" is usually double sides laminated fabric, and then embossed on one side. If the embossed functional fabric, it also get products that combine both aesthetics and functionality. Our company has more than ten kinds of embossed patterns for customers to choose, and can also develop special embossed patterns according to customer needs (higher cost).

The width of the "Neoprene Fabric" is 51 inch / 1.3 meter / 1.41 yard, the volume is large, and the cargo value is not high. For international customers, we use express to send A4 size samples, large orders use sea. send products of full-size by express or air is very expensive, so DIY or small orders are not appropriate. It is suggested to seek local distributors to purchase the products, or to order end products directly from our product department.

Embossed Neoprene Skin

Explain: "Embossed Skin" use neoprene skin to embossed, and the effect is similar to that of the embossed cell, but the surface strength is higher than the embossed cell. Fine skin and shark skin are the most common varieties.

Applications: Wetsuit, surf suit, gloves, sports protective gear and bag etc.

Embossed Neoprene Cell

Explain: "Embossed Cell" use neoprene cell to embossed, can increase the surface strength and anti-slip effect. Shark skin is the most common variety.

Applications: Gloves, sports protective gear, bag and pad etc.

Embossed Neoprene Fabric

Explain: "Embossed Fabric" use neoprene fabric to embossed, can enhance the design, if the embossed on functional fabric, it also get products that combine both aesthetics and functionality.

Applications: Wetsuit patches, sports protective gear, gloves, shoes, bag and pad etc.

Existing Embossed Pattern (Can be used directly):

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Special Note: The above samples are embossed fabric, but most of the patterns are also applicable to embossed skin and embossed cell.

Neoprene Material Explain:

Normative Interpretation: "Neoprene" = "CR" ≠ "SCR" ≠ "SBR"

"Neoprene" just refers to the "CR" (Chloroprene Rubber), but now the industry "Neoprene" include "CR" (Chloroprene Rubber), "SCR" (Chloroprene & Styrene Butadiene Rubber), "SBR" (Styrene Butadiene Rubber).

Neoprene Sponge Color:

| Neoprene Type | CR | SCR | SBR |

| Sponge Color | Black, Cream | Black, Cream | Black, Cream, Aqua, White |

Neoprene sponge color is black, cream, aqua and white. Usually we use black, but if light color fabric is laminated, the use of cream, aqua or white neoprene sponge is better, this collocation can better reflect the color and bright of the light color fabric. If use the black neoprene sponge will light color fabric dark and distorted. But the cost of cream, aqua or white neoprene sponge is higher than the black neoprene sponge.

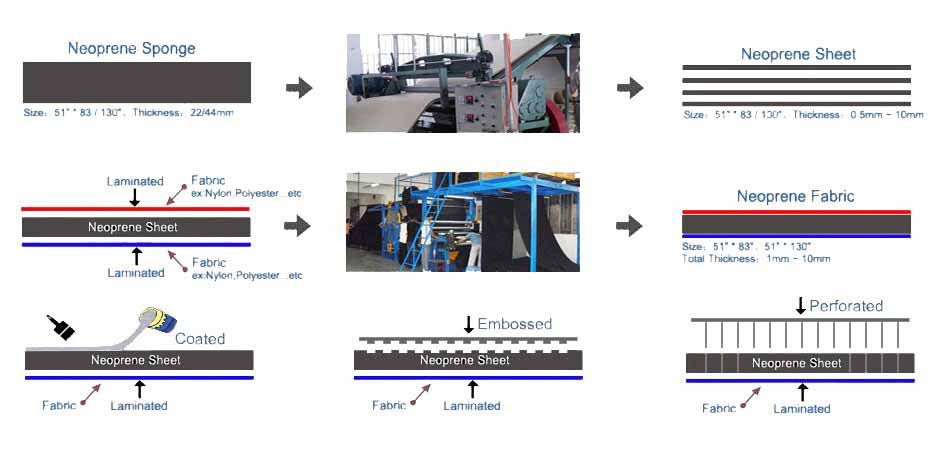

Neoprene Sheet / Fabric Size & Thickness:

| Size (inch) | 51″x83″ | 56″x83″ | 60″x83″ |

| 51″x130″ | 56″x130″ | 60″x130″ | |

| 51″x170″ | 56″x170″ | 60″x170″ | |

| 51″x260″ | 56″x260″ | 60″x260″ | |

| Thickness | 0.5mm - 10mm | ||

Neoprene sponge is produced by foaming mold. The size of the mold defines the size of the neoprene sponge so the size of the neoprene sponge defines the size of the neoprene sheet / fabric.

Neoprene Fabric Quotation Explain:

Usually use "Sheet" or "Piece" as the unit of quotation, in which the cost of neoprene sponge is calculated by thickness, and the cost of fabric and processing is calculated by surface: "Neoprene Sponge Cost" (Thickness, Size and Type) + "Fabric Cost" (Size and Type) + "Processing Cost" (Laminated / Coated / Embossed / Perforated).

We do not recommend the use of "Meter" or "Yard" as the unit of quotation, because the actual length of the neoprene sponge block will be longer than the standard size. Using "Meter" or "Yard" as the unit of quotation is beneficial to the factory and unfair to the customer.

Many customers feel that using "Meter" or "Yard" as the quotation unit will get continuous products, and using "Sheet" or "Piece" as the quotation unit will get single piece product, that it is incorrect. The product is continuous or single piece, and has nothing to do with the unit of quotation, only related to the packaging method, "Carton Package" and "Roll Package" are continuous products, and "Crate Package" is a single piece product.

Continuous Product Explain: We use glue to connect the neoprene sponge and then laminated the fabric so that the neoprene fabric looks continuous. But because the neoprene sponge in the middle layer has a connected by glue, can not use continuously, can only use sheet-by-sheet.

Neoprene Fabric Production Processing:

Limestone Based Eco-Friendly Rubber Sponge Can Fulfill The Below International Standards:

| Oeko-Tex Standard 100 |

Class II |

| REACH | 151 substances in the Candidate List of Substances of Very High Concern (SVHC) for Regulation (EC) No 1907/2006 concerning the REACH |

| RoHS | Restriction of Hazardous Substances - RoHS 2.0 Directive 2011/65/EU Annex II; Recasting 2002/95/EC |

| CPSIA | USA Public Law 110-314 (Consumer Product Safety Improvement Act of 2008, CPSIA) - 1) Lead in accessible substrate materials 2) Phthalates |

| PAHs | Comply with (Category 2) of ZEK 01.4-08 of German ZLS and its amendments |

| Toxic Elements | Migration of Certain Elements - EN 71-3:1994+A1:2000+AC:2002 |